Description

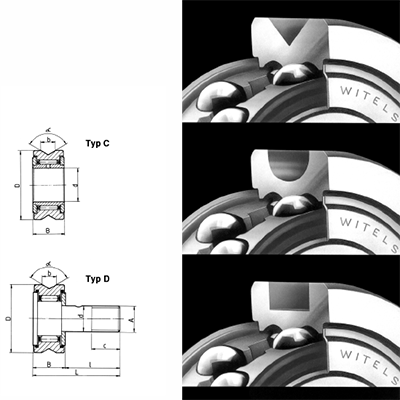

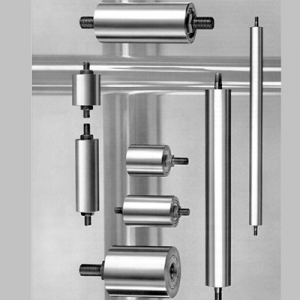

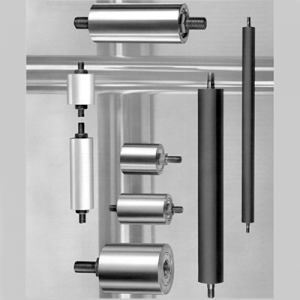

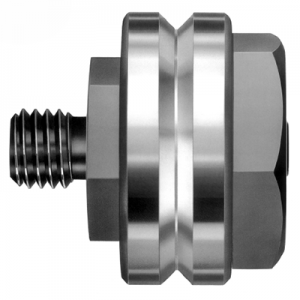

The WN and WK straightening roll series is designed to guide and straighten or guide material being processed through straighteners. The WN WK rolls are designed and built in the German tradition of high quality and have a tolerance of 620 DIN and utilize needle bearings for high load applications.

Witels straightening rollers are generally sealed or shielded on both sides and are lubricated at the factory with high-quality lithium soap grease and extremely adhesive oils which assure a lifetime lubrication. In the case of very unusual working conditions like: low and high temperatures, high speed, humidity, chemical fumes or dust, it is possible to lubricate the rollers again or possibly to use other kinds of grease. The lubricating oils are normally used from -20 °C to +140 °C.

This roller suits a wide variety of applications. They are available from 16mm diameter to 90mm diameter with vee grooves as well as “U” grooves. On a custom basis, other types of profiles are possible.

This high quality and robust designed roller is suited for wire applications but also is used for tubing, cable and other materials. Witels-straightening rollers are made of high quality ball bearing steel: 100 cr 6