Description

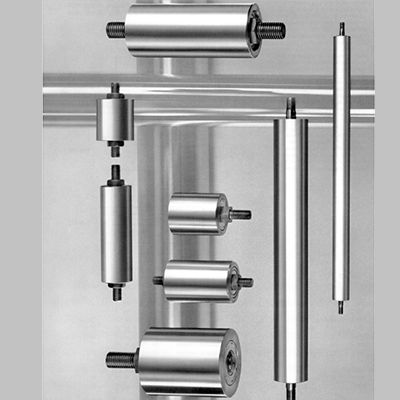

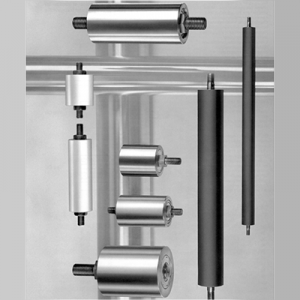

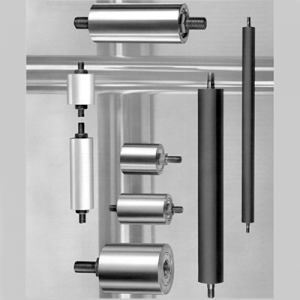

Cromax, a steel of exceptional cleanliness and very close tolerances, is used in the C series guide rolls. This same high standard distinguishes our chromium plating, in terms of adhesion, corrosion resistance and surface smoothness properties, which can make all the difference between endurance and failure in the finished guiding rollers. Cromax guiding rollers last longer.

Chromium layer μm min. 20. Ø – Tolerance ISO f7, f8, h9.

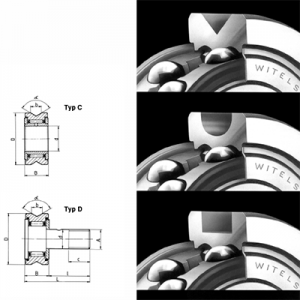

Witels guide roller bearings used in the rollers are generally sealed or shielded on both sides and are lubricated at the factory with high-quality lithium soap grease and extremely adhesive oils which assure a life-lubrication. These rolls are available in diameters of 20mm up to 110mm diameter in customer needed lengths.

In the case of very unusual working conditions like: low and high temperatures, high speed, humidity, chemical fumes or dust, it is possible to re-lubricate the rollers or possibly to use other kinds of grease. The lubricating oils are normally used from -20 °C to +140 °C.

This high quality and robust designed roller is suited for wire applications but also is used for tubing, cable and other materials. Witels uses bearings in the rollers made of high quality ball-bearing-steel: 100 cr 6.

.