Description

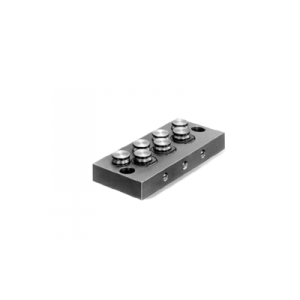

A large initial bend range has a negative effect on the possible quality of straightening. Straightening in the Killing set® produces a constant wire bend without the need for continuous checking and readjustment of the follow-up straightening device. The TR Killing set® has a solid body in which the axes of the three rollers are mounted in fixed position (non-adjustable). The roller bearings are of cassette-type design, (i.e., the straightening roller and its bearing are separate). This results in the following advantages:

- the groove does not weaken the outer ring of the bearing (as in the case with conventional straightening rollers),

- separation enables effective protection of the bearing from dirt,

- higher straightening speeds are possible by using smaller bearings.

- Grease nipples are provided for lubricating the bearings.

The Killing set® has one small roller and two large rollers. The diameter of the small roller (at the exit end) is the same as that of the rollers on the follow-up straightening device. The Killing set® is arranged after the coil (reel) so that the wire first makes an “S” loop around the two large rollers before exiting via the small roller in the direction of the follow-up straightener.

Wire is straightened in the Killing set® with neutral stress. Its looping angle around one of the two large rollers exceeds 180°. The wire’s material parameters are affected by alternate hardening processes. Severe alternate bends are induced with small bending radii, reducing the wire’s bend fluctuations and changing its state of residual stress. Bends are reduced in addition by the higher pull-off force. The wire leaves the device with a constant residual bend.

The TR is built in the German tradition of high quality and is suited for material diameters from nearly 0mm to 3mm OD in five different sizes.