Description

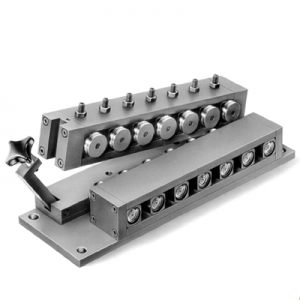

Minimized deformation under load, high precision and a reliable quick-response quick opening mechanism are features of the newly developed RS straightening units.

Built in the German tradition of high quality, these straighteners suit a wide variety of applications and are available in single, double or more planes with an easily added connection base.

The roll diameter and the distance between straightening rolls have been optimized in order to be able to straighten process materials that have a wide range of diameter sizes. The straightening rolls can be re-greased and are prepared for resisting high speeds and high loads. As an option alternative roll materials or specific coatings can be realized.

Straighteners in the RS series are available in five sizes at the present time, which allows straightening wire between 0.8 mm and 9.0 mm diameter.

Users will like the easy operation caused by the quick closing mechanism and the roll adjustment mechanisms located only on one side of the straightener. This is most commonly used in wire applications but also can be used for tubing, cable and other materials. We use the highest quality roller bearings and vee grooves are standard, but other profiles are available on customer request. There are many options available and one of the more valued is the digital roller position indicators that substantially reduce set up time.