Description

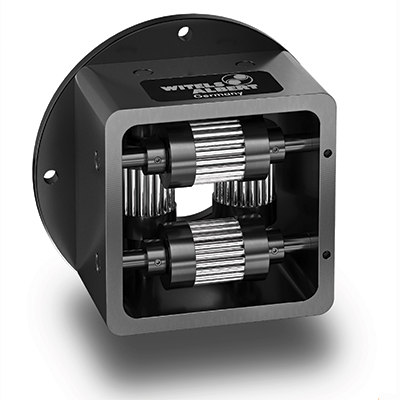

The RK HM Roller Box model is the most rugged guide in our line for use primarily in solid wire applications. It is built in the German tradition of high quality and readily available with attractive pricing.

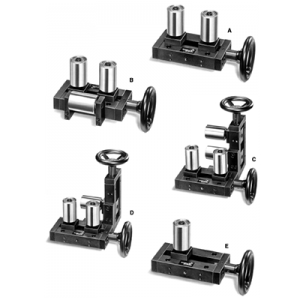

This guide suits a wide variety of applications. One popular use is before drawing machines to guide after static payoffs.

This high quality and robust design is suited for material diameters from about 10mm to 30mm OD in two different sizes.

The roller designs of the newly developed roller guide series, RK HM, use tungsten carbide bars placed over the roll circumference. The bars are supported by a rotation-symmetrical design element, which also houses the bearings of a guide roller and the axel studs.

Due to the gaps between the individual bars, the effect of the automatic proportional descaling of the process material results when guiding wire rod. Nevertheless, if the tungsten carbide rods installed in the contact area with the wire are worn out after some time, they do not have to be replaced. A simple turn around the longitudinal axis by 90° increases the service life significantly. The disassembly and assembly required for this purpose can be carried out quickly and easily within the scope of maintenance.

The RK HM is most commonly used in solid wire applications but also can be used for tubing, cable and other materials with consideration given for size and roll materials.

We use the highest quality roller bearings and hardened steel 62HRC roll sleeves as standard. We offer a number of other roll type possibilities for specific applications to tailor to unique demands including sleeves in different materials like stainless steel.

This unit also can be customized to suite unique applications on request.