Description

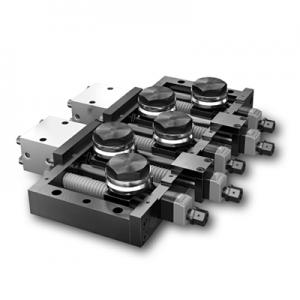

Straighteners PR NT series are equipped with identical sized rolls having a different spacing in the process material direction and is built in the German tradition of high quality. The roll diameter and the roll spacing have been optimized by using our sophisticated process simulation program in order to be able to straighten process materials that have a wider range of sizes. This allows, for example, the usage of 40 mm rolls for processing wire sizes in between 2.0 mm and 6.5 mm and the usage of 52 mm rolls for wire sizes from 6.0 mm to 10.5 mm.

Depending on the size the smaller or the larger spaced rolls should be adjusted. The remaining non-adjusted rolls guide the material and keep the zero line in relation to upstream and/or downstream processes.

This straightener suits a wide variety of applications and is available in single, double or more planes with an easily added connection base plate. This high quality and robust design is suited for material diameters from nearly 0mm to 16mm OD and is supplied with 9 rolls per plane in four different sizes.

The PR NT is most commonly used in wire applications and is often used for tubing, cable and other materials.

We use the highest quality roller bearings and vee grooves are standard, but other profiles are available on customer request. We offer a number of roll type possibilities for specific applications to tailor to unique demands including sleeved roll with outer rings in different materials like stainless steel, PET plastic and hardened steel. There are many options available and one of the more valued is the digital roller position indicators that substantially reduce set up time.