Description

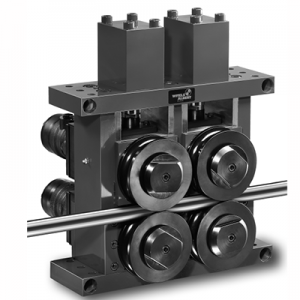

The NAH 160 two roll feeder is designed for round steel wire with diameters between 15 mm and 40 mm and is built in the German tradition of high quality. Hydraulic clamping of the process materials and factory-installed, direct-drive hydraulic motors for the shafts or feed rolls provide very high performance.

Depending on the upstream and downstream roll straightening process, the feed force needs to be as high as 10 kN for these process materials.

Despite the compact overall dimensions, the maximum opening of the feed throat on the drive unit is 60 mm. Process material with a minimum curvature radius of around 300 mm can be inserted into the open feed throat.

The NAH 160 drive unit can be installed horizontally or vertically using the mounting holes provided. As a general rule, we recommend that the mounting position corresponds to the primary curvature plane of the process material. The NAH 160 drive unit is supplied as partly completed machinery (as defined in 2006/42/EC) without protective equipment and without controller. A hydraulic subsystem for the process material clamping and the hydraulic motors is customer supplied. The NAH 160 can be used on horizontal support arm decoilers or upstream and/or downstream from individual bull blocks. Option for an electric motor version is possible as the NAE and either supplied by Witels Albert or the customer.