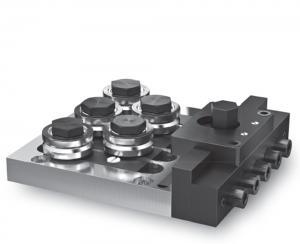

By using new materials and new standard parts, multiple usage of single parts and a high developed assembly and production, the new straighteners RT and RTS series stand for the performance. They are available with 5 or with 7 individually adjustable rolls.

By using new materials and new standard parts, multiple usage of single parts and a high developed assembly and production, the new straighteners RT and RTS series stand for the performance. They are available with 5 or with 7 individually adjustable rolls.

The RT series straighteners don’t have a quick open/close mechanism; the RTS series straighteners do.

RTS straighteners:

A cam-controlled excenter, protected against dust and dirt deposits, is used for the quick opening and closing. RTS series can be opened and closed quickly and easily with only a small amount of force, as a cam controlled excenter is used for the quick opening and closing. The complete new mechanism for opening and closing a straightener an RTS series wire straightener is very robust and reliable, as it is protected against dust and dirt deposits formed from e. g. drawing soap and coating chips.

RT straighteners – Retrofitting

Because the straighteners RT and RTS series have the same basic frame in terms of size and straightening range and, as the designs do not use pinned roll adjustment spindles, RT straighteners can be converted to RTS straighteners at any time. That means that also the customer can choose to upgrade to the quick opening/closing mechanism at any time.

As you know, each straightener is equipped with straightening rolls in two rows. However, two versions are offered, using a different number of straightening rolls dedicated to the side of the straightener with the roll adjustment screws.

By using different straightener versions a perfect adaptation is possible, considering the wire transport direction, the location and the orientation plus the turning direction of the spool respectively of the coil. Bad straightening results by lost bending operations are history, whatever the turning direction of the coil respectively of the spool is.

All the RT and RTS models cover a wire size range between 0.1 and 9.0 mm. In total eight unit sizes are offered.

All models are prepared for managing double-plane straighteners using two straighteners and a so called connecting bracket in between the units. Certainly the connecting brackets can be retrofitted, which also supports the design of customized straightening systems consisting of three or four single plane straighteners at any time.